Correct material preparation

Processing of plastic waste

We offer various solutions for material processing in recycling. The appropriate solution should always be selected based on the residual materials or waste to be recycled.

Impact Air Systems

Zigzag classifier

The zigzag air classifiers are ideal for free flowing materials with low moisture and uniform size. In addition, the materials to be separated should have significant density differences. This is the case, for example, when separating glass – metal – stone from paper – foil – dust – plastic.

These classifiers can be used in many different applications. They are suitable, among others, for recycling of electronic or electronic – waste equipment, industrial waste, residential waste, recovery of glass and substitute fuels.

Technical data

Material size

max. 60 mm

ROI

< 6 months

Zigzag width

800 - 1200 mm

Impact Air Systems

Air drum separator

Impact Air System’s air drum separator uses a rotating drum and separates materials based on density, shape and aerodynamic properties. It is used for separating mixed material streams. The material mixture falls from the conveyor belt, then passes through the high velocity air stream and is either carried over the drum, or falls unaffected in front of the drum.

Technical data

Wide

900 - 2000 mm

Impact Air Systems

Extraction systems

Impact Air Systems’ exhaust systems and ventilation systems are suitable for a wide range of industries and applications. These are used, for example, in paper mills, by packaging manufacturers, in printing plants, as well as in plants for generating energy from waste and in material recycling plants. In addition, humid or warm air can be removed and replaced by fresh air. which can significantly reduce temperatures, moisture content or unwanted odors.

Impact Air Systems

Filter systems

The reliable and robust LRK700, LRK1000 and LRK1400 plastic shredders are used in the plastics processing and recycling industries for regranulation, in-house recycling and volume reduction.

Like all UNTHA shredders, the LRK plastic shredders can be operated as a “stand-alone solution” or integrated into complex systems. High throughput, high availability and a precisely definable granulate guarantee the user high economic efficiency of the versatile single-shaft shredders.

Technical data

Throughput

0,1-1000kg/h

Engine power

3000 rpm

Funnel volume

15 dm3

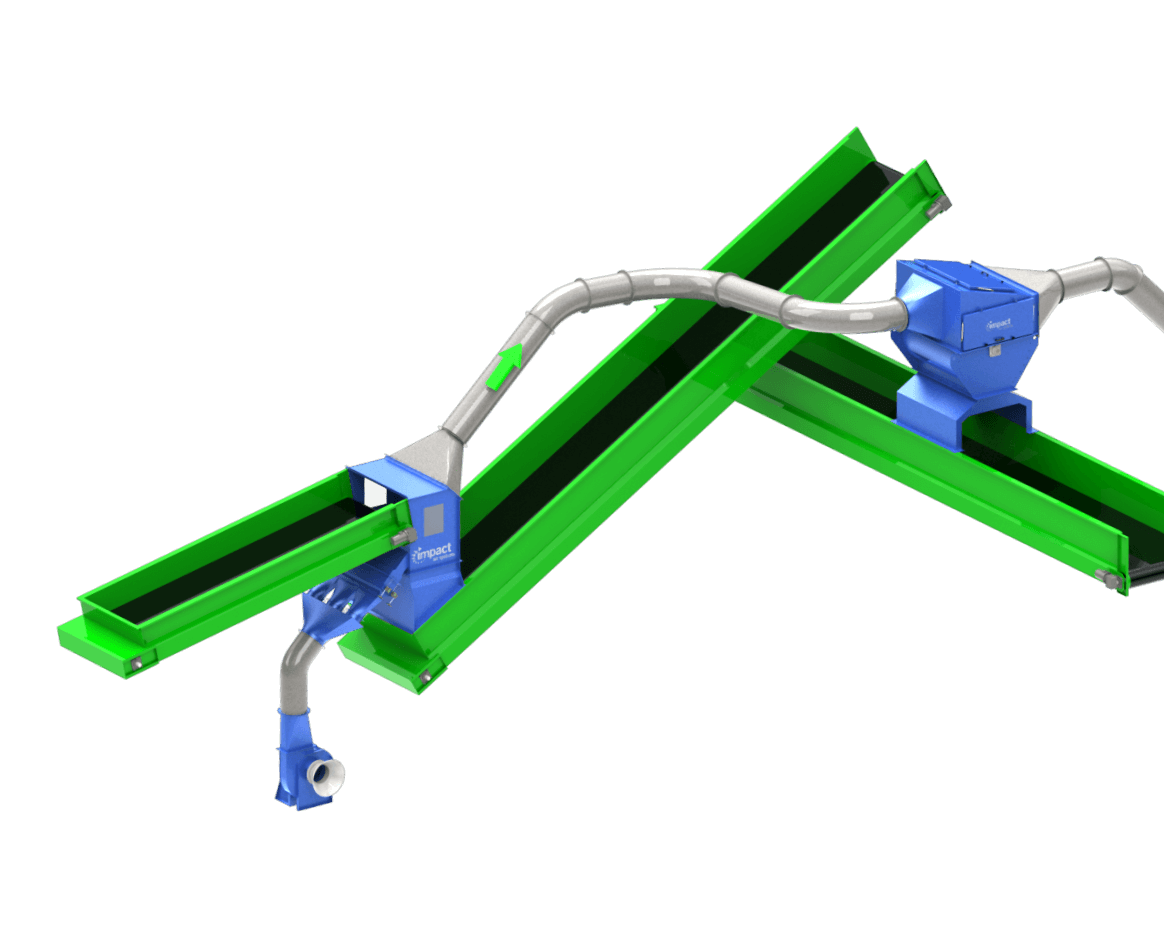

Impact Air Systems

Conveyor systems

The reliable and robust LRK700, LRK1000 and LRK1400 plastic shredders are used in the plastics processing and recycling industries for regranulation, in-house recycling and volume reduction.

Like all UNTHA shredders, the LRK plastic shredders can be operated as a “stand-alone solution” or integrated into complex systems. High throughput, high availability and a precisely definable granulate guarantee the user high economic efficiency of the versatile single-shaft shredders.

Technical data

Throughput

0,1-1000kg/h

Engine power

3000 rpm

Funnel volume

15 dm3

We are here for you

Get in contact with us

Do you have any questions about our recycling solutions? Feel free to contact our sales staff or stop by for a coffee!