Reliable metal separation

Metal separators & metal detection systems

The metal separators or metal detection systems from Sesotec can be used for all types of bulk materials and are ideally suited for granulates, ground materials, flakes and for coarse or fine-grained powders.

Sesotec

Metal separator for free fall applications

The RAPID VARIO-FS metal separator is used to inspect bulk materials in free-fall conveying lines. It detects all magnetic and non-magnetic metal contaminants (steel, stainless steel, aluminum, …) – even if they are enclosed in the product. Metal impurities are eliminated via the reject flap (“Quick Flap”). The metal separator RAPID VARIO-FS is mainly used in industries with low hygienic requirements.

Technical data

Nominal width

30 - 250 mm

Material

Granules, regrind & flakes

Sesotec

High performance metal separator for free fall applications

The RAPID PRO-SENSE metal separator is mainly used for quality control (product purity) in the production and compounding of plastic granules. Typical application is immediately before filling into bigbags, octabins or silos. In addition, the metal separator is also used for quality control in the incoming goods department of plastics processing companies (product purity, machine protection).

Technical data

Nominal width

50 - 250 mm

Material

Granules, regrind, flakes & powder

Sesotec

Mobile metal separator

For manufacturers and processors of plastics, loss of granules in production means a reduction in productivity in addition to the subsequent impact on the environment. The RE-SORT metal separation unit reliably removes metal particles from plastic granules that have already been discharged from the production process. The processed product can be returned to the material stream.

Technical data

Nominal width

50 - 250 mm

Material

Granules, regrind & flakes

Sesotec

Metal separator for pneumatic conveying lines

The GF metal separator is used in suction or pressure conveying lines to protect injection molds and processing machines. Often, even the smallest metal particles in the plastic melt are the cause of costly malfunctions during injection molding, extrusion and blow molding. With the increasing processing of regranulates and regrind, the proportion of these metal impurities is rising. Clogged nozzles, filters and hot runner systems often enough lead to production downtime, shutdowns and delayed deliveries.

Technical data

Nominal width

50 - 150 mm

Material

Granules & regrind

Sesotec

Metal separator for standing material column

For the inspection of slow-flowing or stationary columns of material, our metal detectors are installed directly in front of injection molding machines, extruders and blow molding machines. There, with minimal loss of good material, you remove all magnetic and non-magnetic metals, even if they are enclosed in the product.

Technical data

Nominal width

30 - 150 mm

Material

Granules, regrind & flakes

Sesotec

Analysis systems

For manufacturers and processors of plastics, ensuring consistently high material quality is a crucial profitability factor. Our analysis system FLAKE SCAN was explicitly developed for use in plastics recycling as well as plastics processing and enables a reliable random sample analysis according to plastic types, colors and metal foreign bodies within minutes.

Technical data

Throughput

max. 20 kg/h

Material

Granules, regrind & flakes

Sesotec

Magnetic technology type SAFEMAG

The SAFEMAG pipe magnet was specially developed for use in the plastics industry. Various granules, up to a particle size of 6 mm and a temperature of up to 100° C, can be investigated in standing or slow-flowing columns of material.

Technical data

Nominal width

40 - 60 mm

Magnetic strength

700 mT

Sesotec

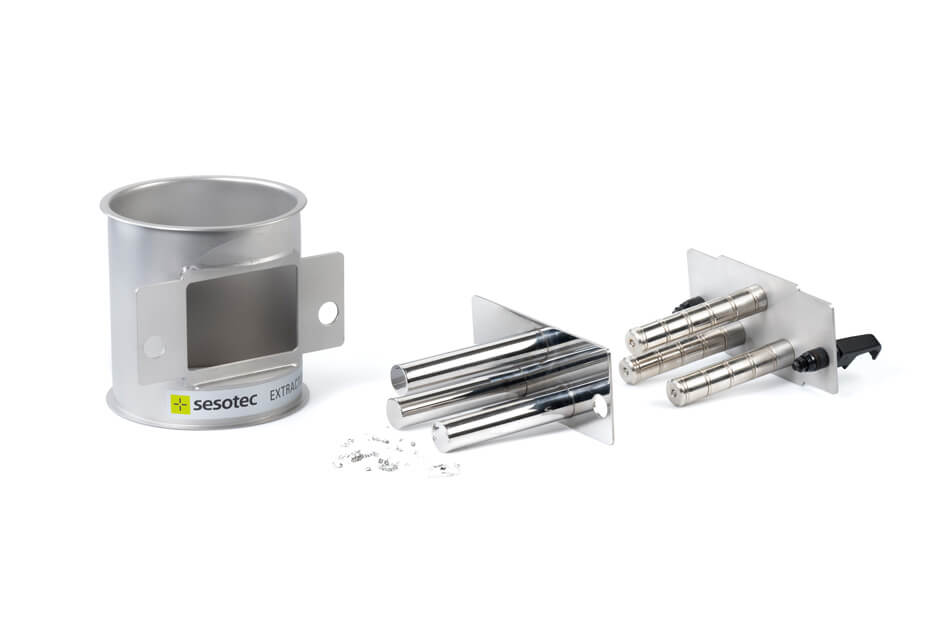

Magnetic technology Type EXTRACTOR

Our magnetic separators for material columns have been specially developed for use in the plastics industry and can be easily and quickly integrated into material columns of granulates. They are installed at or just before the material intake of, for example, injection molding machines, extruders or blow molding machines. By safely separating ferromagnetic particles, they provide highly efficient protection against plant downtime and costly repairs.

Technical data

Nominal width

40 - 60 mm

Magnetic strength

800 mT

Sesotec

Magnetic technology type MAGBOX

Our magnet systems for free-fall applications can be quickly and easily integrated into all production lines for powdery and granular bulk materials. Whether you manufacture plastics, foodstuffs, medicines or other products – with the tubular magnets you reliably protect consumers and machines from magnetic foreign bodies.

Technical data

Nominal width

40 - 60 mm

Magnetic strength

700/900 mT

We are here for you

Get in contact with us

Do you still have questions about our material handling solutions? Feel free to contact our sales staff directly or send an e-mail to office@sipa.at.