Other peripheral equipment for the plastics industry

Miscellaneous for the plastics industry

We have accompanying equipment and machinery for the plastics industry in use. In addition to conveyors, we also offer big bag stations, depot stations, separators and rotary distributors. We will be happy to advise you personally on your specific application.

Beccaria

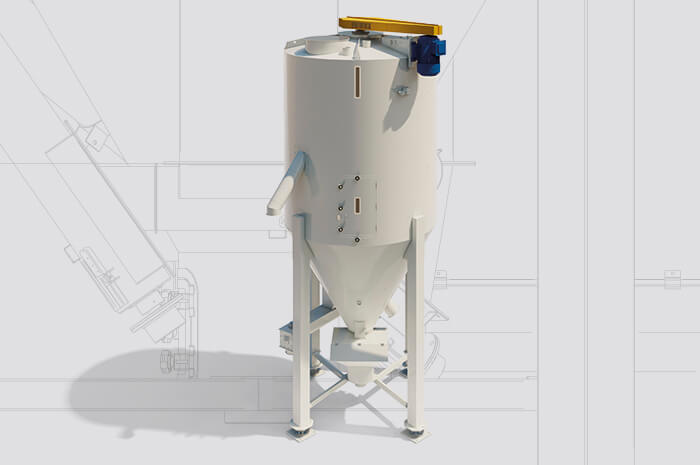

Storage and mixing silos

Vertical mixing silos for homogenizing granules, regrinds and flakes made of painted steel or stainless steel AISI 304. These mixing silos are available in different designs and sizes and can be equipped according to customer requirements.

Storage silos made of stainless steel or aluminum up to a diameter of 4.2m and a capacity of 250m³ or in segmental construction up to a diameter of 6m and a capacity of 400m³.

Technical data

Storage silo

500 - 50000 liters

Mixing silo

0,5 - 250 m³

Diameter

2415 - 4200 mm

Beccaria

Big Bag emptying and filling stations

The Big Bag emptying and filling stations are made of painted steel or stainless steel and are ideally suited for filling or emptying granulates, regrinds, flakes and powders. Height adjustment by means of a telescopic system for different bag sizes is standard. Infeed and discharge aids, crane loading, various options and designs as single or double station are possible.

Technical data

Big Bag

max. 2000 kg

Beccaria

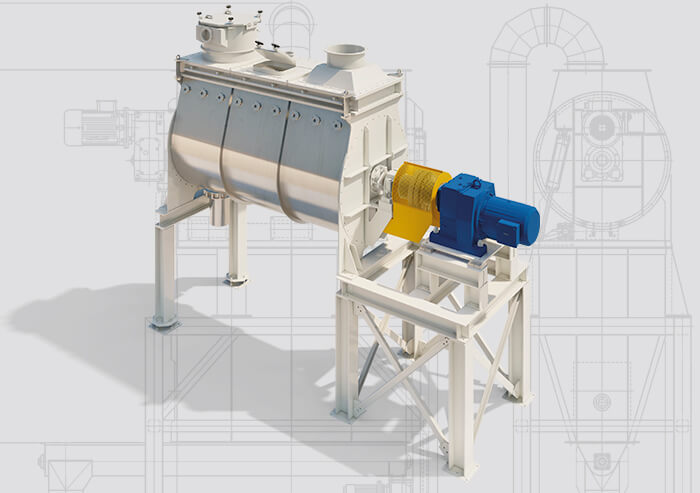

Horizontal mixers

The horizontal mixer Mod. MA/2 has a special design of batch mixing system, based on two parallel shafts. The horizontal mixer is dimensioned for the toughest applications and ensures perfect mixing of powdered and granular materials, even with different specific weights. Due to the possibility of liquid addition, the mixer is used in a wide range of industries.

Technical data

Volume

2000-10000kg/h

Engine power

2x 5,5kW up to

2x 22kW

M Conveyor Systems

Conveyor belts

Whether designed as a straight, angled or apron conveyor, the torsion-resistant frame construction offers high stability thanks to extruded aluminum profiles. Mobile versions, precise seals between belt and side guide, a wide range of different belt straps complete the program.

M Conveyor Systems

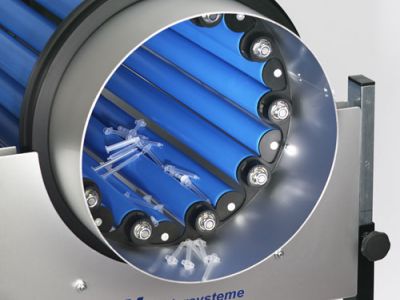

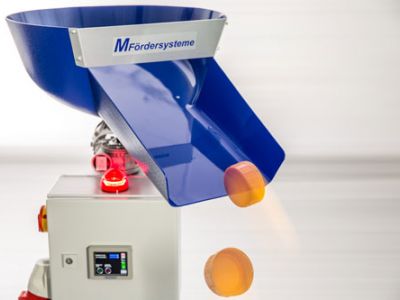

Sprue separators

The separators for all-round use, for sorting injection molded parts and sprues. With the aid of the central adjustment, the separating drum can be easily and precisely set to a new part/gate combination in just a few seconds. All roller pairs can be adjusted synchronously and steplessly with a single handle via a chain drive and locked in place by a central locking device. With the compact, mobile base frame, the drum is infinitely adjustable in height and inclination and can thus be optimally adapted to the production conditions.

M Conveyor Systems

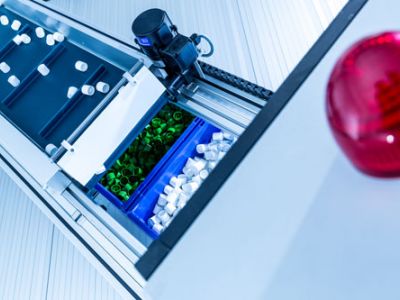

Depot stations

Single-row and multi-row depot stations for filling containers or bags offer piece-precise filling by pulse counting. Adapted to your number and container sizes, there are no interruption times and the highest operational reliability. The high storage capacity for night or weekend productions as well as the easy operation through fixed programs simplify your production workflow.

We are here for you

Get in contact with us

Do you still have questions about our material handling solutions? Feel free to contact our sales staff directly or send an e-mail to office@sipa.at.